5S vs. 6S

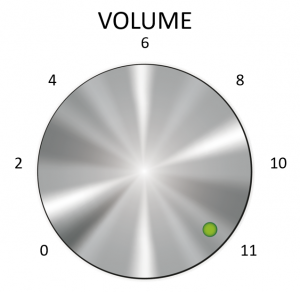

“It’s one louder, isn’t it?”

When I originally wrote that headline, I thought of that wonderful scene on This is Spinal Tap where the musician was talking about how his speakers were louder than anyone else’s. When everyone else’s had a volume knob that went from 0 to 10, his went up to 11. The only thing that was different about his speaker was the volume knob. It wasn’t actually louder, but in his mind, 11 was obviously louder than 10. That’s how I jokingly first thought about the 5S vs. 6S debate.

When I originally wrote that headline, I thought of that wonderful scene on This is Spinal Tap where the musician was talking about how his speakers were louder than anyone else’s. When everyone else’s had a volume knob that went from 0 to 10, his went up to 11. The only thing that was different about his speaker was the volume knob. It wasn’t actually louder, but in his mind, 11 was obviously louder than 10. That’s how I jokingly first thought about the 5S vs. 6S debate.

One of the variations that I sometimes see in the continuous improvement world is teaching and implementing 6S rather than 5S. And while it’s easy to be silly about the debate, it’s definitely worth discussing.

For those unfamiliar with 5S, it is a disciplined methodology for creating and maintaining a clean, organized, efficient, and safe workplace. The five Ss represent the five structured stages of implementing the discipline. The Ss stand for: Sort, Shine, Set, Standardize, and Sustain.

A VERY concise explanation of the Five Ss:

Sort: identify only the inventory, tools (including information tools) and maintenance items absolutely required to support the daily activities of the work area.

Sort: identify only the inventory, tools (including information tools) and maintenance items absolutely required to support the daily activities of the work area.

Shine: raise the work area to a “good as, or better than, new” condition, and establish a work area that is a visual benchmark.

Set: Identify the optimum location for each inventory item, tool and work area supply.

Standardize: establish simple visual signals to ensure that the higher level established in the Sort, Shine, and Set become the new standard.

Sustain: continuously maintain and even improve upon the condition of the workplace from that attained during the initial 5S events.

What About That 6th S?

Those five Ss are really good to have, and I can’t recommend a robust 5S program enough. However, there are some out there that think a 5S program is lacking one very important S. That S stands for Safety. There are some practitioners who implement Safety as an extended version of 5S that they simply refer to as 6S.

Practitioners of 5S will tell you that safety is integrated into, and is an important component, of each S. 6S proponents feel safety is important enough to deserve its own stage of implementation and will have specific safety-related tasks that are part of that stage.

What’s my opinion? I tend to lean more toward 5S. The reason I do this isn’t because I don’t think safety deserves its own stage. Quite the contrary, I believe safety is important enough to deserve its own unique initiative, separate from all other roles and functions within an organization. At Utah Lean Six Sigma Training Center we teach that all of continuous improvement is based on the respect that we have for our colleagues and coworkers. A major part of that respect is an emphasis on safety.

Do What Works for YOU!

All that being said, here is one thing I know for certain: DO WHAT’S RIGHT FOR YOUR ORGANIZATION! If that means a 5S program with an independent safety program, then great! If that means you implement a robust 6S program and roll safety into that initiative, then great! The number of ways to implement continuous improvement are as numerous as the unique organizations dotting the globe. But whatever you do, give safety – and the people you work with – the respect they deserve.

Want to Learn More?

The Yellow Belt class taught at Utah Lean Six Sigma Training Center covers, among other useful topics, the details of 5S. The Green Belt course covers in detail how to implement, support, and maintain a 5S implementation along with the cultural aspects of sustainment. We have classes taught throughout the year, so check out the course calendar and register for your training today!

See you in class!