Tell me if you’ve heard this Lean joke before: A husband and wife walk into a bar the store…

The Setup

Two weeks prior, they had ordered a series of frames for new family photos to adorn their living room wall. They sat with the salesperson, weighed the options, paid a deposit, and left with an eagerness for the joy the images of their beloved family would add to their home. The photos would be particularly nice for the upcoming family summer party they were hosting in the very near future.

The couple waited patiently for those two weeks to pass. During this period of patient anticipation, they prepared the wall by removing the old photos and adding a touch of new paint. They measured and located where each hook would be placed.

The Crisis

Finally after the two weeks of waiting they excitedly drove back to the store to pick up their promised framed photos. They walked to the will call window, presented their receipt, paid the remainder of their bill…

And were told their frames weren’t ready.

The Fake Victory

Exasperated, the now-frustrated couple inquired as to why their frames weren’t ready. A litany of excuses were offered, followed by many apologies, followed by zero excuses. The proverbial ball had simply been dropped.

In a blur of activity, store workers swarmed like the bees in a disturbed hive. One ran to the back room to pull inventory. Another dashed across the showroom to pick up the prints from their storage room. Yet another busy bee disappeared behind a desk to make a series of phone calls, pulling more resources in. At the end of a very hectic 15 minutes the workers proudly presented the couple with their freshly packaged set of framed family photos.

The False Thrill

As the husband and wife left, the workers held a mild celebration. As a result of the (fake) victory, backs were patted. Cheers were raised. Fives were… highed. (Please forgive the author for that last one)

Once the excitement of spontaneous teamwork and the thrill of overcoming this hurdle subsided, work went back to normal. For months, workers fondly recounted stories of “that time we all came together”. Company leaders spoke about it at annual meetings.

Taking off the Rose Colored Glasses – A Lean Perspective

To be fair, using shared trials is a great way to build teamwork. There are, however, better ways to do this. Chief among those better ways are those that don’t include an unhappy customer. The first principle of Lean is to identify value. This means we understand exactly what our customers want and then spend the rest of our efforts in meeting those customer requirements.

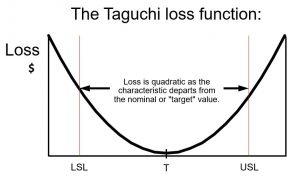

The reality is that even though the team pulled together to get the order done, the victory was false – diminished value was provided to the customer. Yes, the customers got their frames, but as Taguchi taught us, anything that deviates from perfect is a loss of value. These customers got their frames – but they got them late. The company got paid, but what are the chances those customers return again? What are the chances they tell their friends and relatives about their negative experience? How much time did we spend responding to this self-inflicted emergency when we could have been doing value-added work? How much more of this chaos can our employees take before they seek greener, more peaceful and organized, pastures?

See Defects as They Really Are

It does very little good for us to celebrate victory over our problems if we do nothing to learn from them and make sure they don’t happen again. When defects occur, recognize them for what they are: negative experiences that, although they can also be learning experiences, are nonetheless damaging to an organization. Defects should be investigated, analyzed, and eliminated. Controls should be put in place to ensure the defect doesn’t happen again. Basic Lean tools such as 5S, standard work, mistake proofing, and visual management should be implemented. For larger, more systemic problems, formal projects should be organized and given the support and resources needed for success. Lean practices, including those taught in the Utah Lean Six Sigma Training Center courses teach us to pursue problem solving and improvements with relentless determination.

What’s Better Than Fixing Problems?

Fixing a problem, especially when a team really comes together to do it, can be really rewarding. The far better, albeit potentially less exciting, option is making sure the problem doesn’t happen in the first place. In the Utah Lean Six Sigma Training Center Green Belt course, students learn to perform proactive problem solving. Students are taught to analyze a process to determine what could possibly go wrong, prioritize these failure modes, and then implement preventive measures to eliminate the threat of the defect occurring.

Get the Lean Training You Need

Utah Lean Six Sigma Training Center works hard to bring Lean training to Utah that is applicable, attainable, available, and affordable. We stand ready to meet your needs. To help you make the best choice possible when choosing a training provider, we’ve written an ebook to help walk you through a complex decision. Get your free copy here.

See you in class!