by Craig Johnson | Dec 30, 2025 | Education

A Monthly Note from Utah Lean Six Sigma Training Center

This monthly note is designed to respect your time and sharpen your thinking: one useful idea, one real-world insight, and one small nudge toward better work.

One Useful Idea – Continuous Improvement Loves Small Cycles

One of the quiet lies we tell ourselves is that improvement requires huge effort, energy, and perfect timing. Lean thinking disagrees.

At its core, continuous improvement is built on short cycles of reflection and adjustment. Plan something small. Try it. Check what happened. Adjust. No fanfare. No heroics. Just progress.

The most common mistake organizations make is waiting for “the big reset”. The new system, the new year, the new initiative. In reality, improvement compounds fastest when learning cycles are short and frequent.

This quiet week between Christmas and New Year’s is a perfect example. It’s calm, reflective, and mostly free of meetings. In Lean terms, it’s an unusually good moment to check and adjust before the next plan begins.

Lessons for Real Work – Why Kaizens Loves the Calendar Turn

New Year’s resolutions tend to fail because they aim for transformation instead of

calibration.

What actually works is asking better questions:

• What caused friction this year?

• Where did work slow down for no good reason?

• Which problems kept repeating?

In addition to the normal strategic planning, one organization we worked with tasked each leader at every level with picking one recurring annoyance their team had lived with all year. After some calibration (remember: no random acts of improvement!), they focused on fixing those problems. No banners. No slogans. Just relief. That’s everyday kaizen in its natural habitat: modest, practical, and quietly effective.

As you head into 2026, resist the urge to overhaul everything. Improvement doesn’t need a resolution. It needs attention

Before the year officially transitions to 2026, ask this question in your next conversation with

subject matter experts or planning meeting:

“What’s one thing we should stop accepting as normal next year?”

Listen carefully (remember: go see, ask why, show respect!). The answers may be very specific and very fixable.

If you know someone who would benefit from practical, no-nonsense Lean training, we appreciate the introduction, and we show that

appreciation with cash.

• Lean Foundations (Yellow Belt): $20

• Lean Leadership (Green Belt): $50

• Lean Enterprise (Black Belt): $100

Friends, colleagues, and family members all count. This is our simple way of saying thank you.

by Craig Johnson | Feb 24, 2022 | Education

Tell me if you’ve heard this Lean joke before: A husband and wife walk into a bar the store…

The Setup

Two weeks prior, they had ordered a series of frames for new family photos to adorn their living room wall. They sat with the salesperson, weighed the options, paid a deposit, and left with an eagerness for the joy the images of their beloved family would add to their home. The photos would be particularly nice for the upcoming family summer party they were hosting in the very near future.

The couple waited patiently for those two weeks to pass. During this period of patient anticipation, they prepared the wall by removing the old photos and adding a touch of new paint. They measured and located where each hook would be placed.

The Crisis

Finally after the two weeks of waiting they excitedly drove back to the store to pick up their promised framed photos. They walked to the will call window, presented their receipt, paid the remainder of their bill…

And were told their frames weren’t ready.

The Fake Victory

Exasperated, the now-frustrated couple inquired as to why their frames weren’t ready. A litany of excuses were offered, followed by many apologies, followed by zero excuses. The proverbial ball had simply been dropped.

In a blur of activity, store workers swarmed like the bees in a disturbed hive. One ran to the back room to pull inventory. Another dashed across the showroom to pick up the prints from their storage room. Yet another busy bee disappeared behind a desk to make a series of phone calls, pulling more resources in. At the end of a very hectic 15 minutes the workers proudly presented the couple with their freshly packaged set of framed family photos.

The False Thrill

As the husband and wife left, the workers held a mild celebration. As a result of the (fake) victory, backs were patted. Cheers were raised. Fives were… highed. (Please forgive the author for that last one)

Once the excitement of spontaneous teamwork and the thrill of overcoming this hurdle subsided, work went back to normal. For months, workers fondly recounted stories of “that time we all came together”. Company leaders spoke about it at annual meetings.

Taking off the Rose Colored Glasses – A Lean Perspective

To be fair, using shared trials is a great way to build teamwork. There are, however, better ways to do this. Chief among those better ways are those that don’t include an unhappy customer. The first principle of Lean is to identify value. This means we understand exactly what our customers want and then spend the rest of our efforts in meeting those customer requirements.

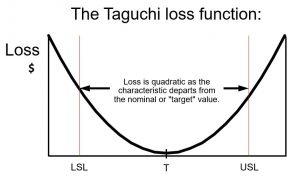

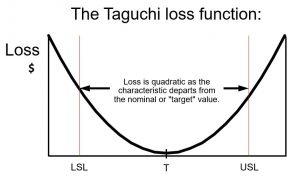

The reality is that even though the team pulled together to get the order done, the victory was false – diminished value was provided to the customer. Yes, the customers got their frames, but as Taguchi taught us, anything that deviates from perfect is a loss of value. These customers got their frames – but they got them late. The company got paid, but what are the chances those customers return again? What are the chances they tell their friends and relatives about their negative experience? How much time did we spend responding to this self-inflicted emergency when we could have been doing value-added work? How much more of this chaos can our employees take before they seek greener, more peaceful and organized, pastures?

Click to Enlarge

See Defects as They Really Are

It does very little good for us to celebrate victory over our problems if we do nothing to learn from them and make sure they don’t happen again. When defects occur, recognize them for what they are: negative experiences that, although they can also be learning experiences, are nonetheless damaging to an organization. Defects should be investigated, analyzed, and eliminated. Controls should be put in place to ensure the defect doesn’t happen again. Basic Lean tools such as 5S, standard work, mistake proofing, and visual management should be implemented. For larger, more systemic problems, formal projects should be organized and given the support and resources needed for success. Lean practices, including those taught in the Utah Lean Six Sigma Training Center courses teach us to pursue problem solving and improvements with relentless determination.

What’s Better Than Fixing Problems?

Fixing a problem, especially when a team really comes together to do it, can be really rewarding. The far better, albeit potentially less exciting, option is making sure the problem doesn’t happen in the first place. In the Utah Lean Six Sigma Training Center Green Belt course, students learn to perform proactive problem solving. Students are taught to analyze a process to determine what could possibly go wrong, prioritize these failure modes, and then implement preventive measures to eliminate the threat of the defect occurring.

Get the Lean Training You Need

Utah Lean Six Sigma Training Center works hard to bring Lean training to Utah that is applicable, attainable, available, and affordable. We stand ready to meet your needs. To help you make the best choice possible when choosing a training provider, we’ve written an ebook to help walk you through a complex decision. Get your free copy here.

See you in class!

by Craig Johnson | Mar 16, 2021 | Education

(Cover image credit: educegroup.com)

Is Virtual Training Here to Stay?

Finding Gratitude in Tough Times

We have a tradition in my home. Every evening at the end of the day the four of us express gratitude for one thing that we experienced that day. Often that conversation is relatively easy and the gratitude is easy to come by. But sometimes it is not. Some days are, well, we’ll say… challenging… to find something for which to be grateful.

For many, the entire year 2020 was one of those days. But just like those not-so-good days, there are things we can be grateful for from the past year. One of the things for which I am very grateful is the advent of virtual training.

Sometimes Our Perception Needs to Change

If you would have asked me a year ago I would have told you in very clear terms that the classes taught at Utah Lean Six Sigma Training Center absolutely could not be taught virtually. How in the world could I possible convert twenty eight team breakout activities into a virtual environment?!

Well, turns out it really wasn’t that bad. And the virtual solution we implemented is actually pretty good! Not only is it an effective platform, but there are some distinct advantages. Students learn the concepts, but also learn methods by which they can use the concepts in a virtual environment in their own business.

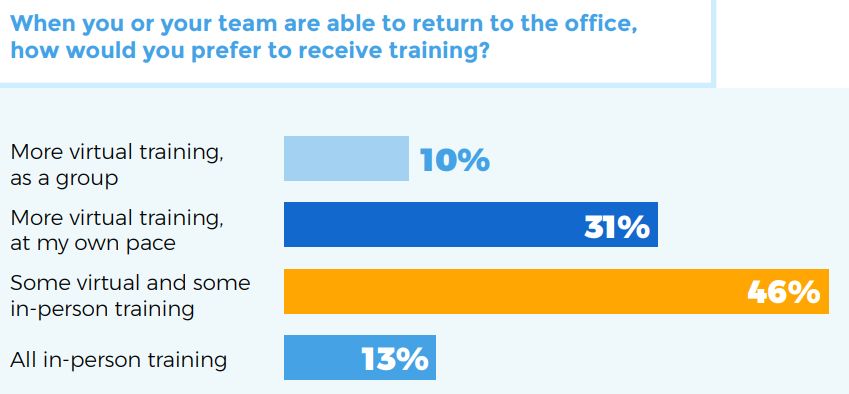

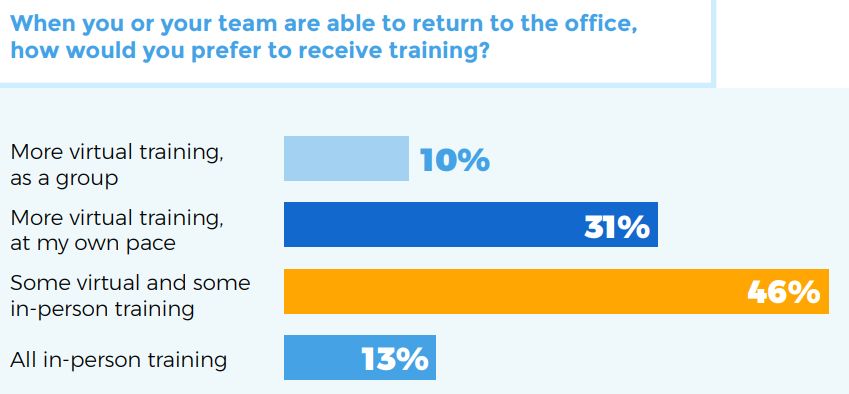

In a recent study by Kahoot, 46% of respondents said learning and development is more important than ever since the shift to remote working. Furthermore, 46% of respondents said they preferred training to continue to be a combination of virtual and in-person.

“The most popular preference for training is a blended learning system, with nearly 1 in 2 professionals saying they would prefer a mix of in-person and virtual training once they can be together at the office.”

My own experience has largely been the same. The level of learning in a virtual environment has been every bit as good as an in-person environment. The bonus of the virtual environment is that students are learning what is being taught, but also learning how they can effectively facilitate a virtual working group.

For example, in the Utah Lean Six Sigma Training Center Green Belt class, we have a team breakout session to practice effective brainstorming. When we teach in-person, groups stand together with Post-It notes in hand. In a virtual environment, students go into a Zoom breakout room and use the sticky notes tool in Lucidchart. (Side note: if you haven’t checked out Lucidchart already, do it. Now.) By doing so, the students learn how to effectively brainstorm, but they also know how to effectively use a free online tool so that they can virtually collaborate with their colleagues.

Virtual Training in 2021 and Beyond

At Utah Lean Six Sigma Training Center we remain dedicated to becoming the premier Lean Six Sigma training provider in Utah. We are passionate about providing training that is applicable to Utah industries, available in a variety of locations, formats, and schedules, attainable in a reasonable amount of time, and affordable for individuals and organizations. We have developed a robust live online format of instruction that dozens of students have successfully completed.

While I do believe that in-person training remains very desirable, I also believe that blended live/virtual training is absolutely here to stay and may even be the ideal solution. The world has shown that not only can we do it, but we can do it very well.

by Craig Johnson | Jan 13, 2021 | Education

“What would this look like if it were easy?”

-Tim Ferris

Sometimes I sit in my simple little commuter car and marvel at what a marvel of engineering it is. Thousands of intricate parts work in near perfect harmony to carry me down the road in what is the relative lap of luxury. I’m in awe of the mazes of wiring and interconnected mechanical parts. It’s stunning to me that these many complex parts and systems on top of subsystems can somehow manage to work!

In the world of continuous improvement we can find ourselves falling prey to the temptation to have intricately complex solutions to every problem. We make our forms, our systems, our processes. Controls are put in place to ensure every intricacy of our bouncing baby process is stable, repeatable, and reproducible. As a result, we find that our new process runs well, but the slightest hiccup reduces the entire thing to a smoking crater. Minor variations cause major disruptions.

I’m not going to tell you that complex solutions are bad because they’re not! Complex problems often require complex solutions. We just need to make sure solutions are applied carefully and strategically.

Because Lean Six Sigma is based on respect for our employees, colleagues, and ourselves, we need to create solutions that are as easy as possible, which is why we follow the adage to “Keep it Simple, Stupid!” or K.I.S.S.

Because Lean Six Sigma is based on respect for our employees, colleagues, and ourselves, we need to create solutions that are as easy as possible, which is why we follow the adage to “Keep it Simple, Stupid!” or K.I.S.S.

Humor aside, it’s the first three letters of that acronym that are really important. We want to keep our solutions as simple as possible. Simplicity in design often means simplicity in implementation. Which means simplicity in practice. Which means effort and expense is low so that labor and money can be spent elsewhere.

As you create new processes or revise old ones remember to ask yourself, “How can I make this simpler?” Or in the words of Tim Ferris, “What would this look like if it were easy?”

Because Lean Six Sigma is based on respect for our employees, colleagues, and ourselves, we need to create solutions that are as easy as possible, which is why we follow the adage to “Keep it Simple, Stupid!” or K.I.S.S.

Because Lean Six Sigma is based on respect for our employees, colleagues, and ourselves, we need to create solutions that are as easy as possible, which is why we follow the adage to “Keep it Simple, Stupid!” or K.I.S.S.