by Craig Johnson | Feb 20, 2020 | Education

Mistake Proofing

Background

Mistake proofing, also known as error proofing, is a concept that has existed longer than anyone can accurately define. Poka Yoke, the Japanese term for mistake proofing, was formally defined and systematized by Shigeo Shingo of Toyota in the 1960’s. It has become a standard for creating processes that are designed to either not be able to produce a specific defect or automatically detect and reject a specific defect. Mistake proofing has been used across industries to create efficient workspaces and to create safe environments. To be able to implement mistake proofing we need to understand the types of mistakes people can make and then be able to put countermeasures in place to prevent those mistakes.

Mistake proofing, also known as error proofing, is a concept that has existed longer than anyone can accurately define. Poka Yoke, the Japanese term for mistake proofing, was formally defined and systematized by Shigeo Shingo of Toyota in the 1960’s. It has become a standard for creating processes that are designed to either not be able to produce a specific defect or automatically detect and reject a specific defect. Mistake proofing has been used across industries to create efficient workspaces and to create safe environments. To be able to implement mistake proofing we need to understand the types of mistakes people can make and then be able to put countermeasures in place to prevent those mistakes.

FMEAs are great tools, but it can be very difficult to look at a process and determine what could possibly go wrong. In the same way that a fishbone (or Ishikawa) diagram helps to add structure to a root cause analysis brainstorming event, we can add structure to our mistake proofing brainstorming as well. Instead of the 6Ms of a fishbone diagram, we use 10 common types of mistakes to organize our thought process.

The 10 Common Types of Mistakes

- Forgetfulness: People forget things when they’re not concentrating

- Misunderstanding: People make mistakes when they come to a conclusion before being familiar with a situation

- Identification: People misjudge situations because the view it too quickly or without enough detail

- Amateurs: Less experienced people tend to make more mistakes than experienced people

- Willful: People ignore rules under certain circumstances

- Inadvertent: People can be absent minded and make mistakes without knowing it

- Speed: When people go too fast or too slow, or speed up or slow down, they can make mistakes

- Standards: People make mistakes when they don’t know how to perform their duties or how success is defined

- Surprise: People make mistakes when something unexpected happens and they don’t know how to deal with the situation

- Intentional: On RARE occasions, people will intentionally make mistakes in order to sub-optimize a process or cause damage

How Does Mistake Proofing Help?

Mistake proofing allows us to reduce the risk of mistakes in a variety of ways. Here are some ways you can implement mistake proofing into your processes:

- Alert people at regular intervals as a reminder

- Enforce standard work and safety requirements

- Highlight critical elements or steps

- Automatically shut down processes or equipment event of a safety concern

- Develop a robust training program

- Give new hires the knowledge, skills, and abilities they need to be effective and safe

- “Don’t practice until you get it right. Practice until you can’t get it wrong.”

- Remove the ability to make incorrect decisions

- Define and display standard work

- Add guards, rails, beams, curtains, etc. to prevent safety events

- Create digital safeguards

- Minimum length of passwords

- Force the correct type of data input (only numbers, for example)

- Create security protocols for networked devices

How To Do It

- Describe the defect – be specific

- Identify the location at which the mistake occurs

- Detail current standard procedures

- Identify potential mistakes or deviations from standards – also look at historical data

- Identify conditions that provoke mistakes

- Perform a root cause analysis to determine why the mistake occurred or may occur

- Identify type of mistake proofing device required

- Create the device, test it, and standardize the new process

by Craig Johnson | Oct 31, 2019 | Education

5S vs. 6S

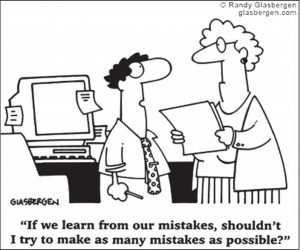

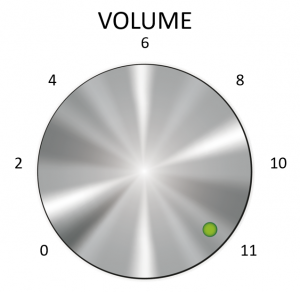

“It’s one louder, isn’t it?”

When I originally wrote that headline, I thought of that wonderful scene on This is Spinal Tap where the musician was talking about how his speakers were louder than anyone else’s. When everyone else’s had a volume knob that went from 0 to 10, his went up to 11. The only thing that was different about his speaker was the volume knob. It wasn’t actually louder, but in his mind, 11 was obviously louder than 10. That’s how I jokingly first thought about the 5S vs. 6S debate.

When I originally wrote that headline, I thought of that wonderful scene on This is Spinal Tap where the musician was talking about how his speakers were louder than anyone else’s. When everyone else’s had a volume knob that went from 0 to 10, his went up to 11. The only thing that was different about his speaker was the volume knob. It wasn’t actually louder, but in his mind, 11 was obviously louder than 10. That’s how I jokingly first thought about the 5S vs. 6S debate.

One of the variations that I sometimes see in the continuous improvement world is teaching and implementing 6S rather than 5S. And while it’s easy to be silly about the debate, it’s definitely worth discussing.

For those unfamiliar with 5S, it is a disciplined methodology for creating and maintaining a clean, organized, efficient, and safe workplace. The five Ss represent the five structured stages of implementing the discipline. The Ss stand for: Sort, Shine, Set, Standardize, and Sustain.

A VERY concise explanation of the Five Ss:

Sort: identify only the inventory, tools (including information tools) and maintenance items absolutely required to support the daily activities of the work area.

Sort: identify only the inventory, tools (including information tools) and maintenance items absolutely required to support the daily activities of the work area.

Shine: raise the work area to a “good as, or better than, new” condition, and establish a work area that is a visual benchmark.

Set: Identify the optimum location for each inventory item, tool and work area supply.

Standardize: establish simple visual signals to ensure that the higher level established in the Sort, Shine, and Set become the new standard.

Sustain: continuously maintain and even improve upon the condition of the workplace from that attained during the initial 5S events.

What About That 6th S?

Those five Ss are really good to have, and I can’t recommend a robust 5S program enough. However, there are some out there that think a 5S program is lacking one very important S. That S stands for Safety. There are some practitioners who implement Safety as an extended version of 5S that they simply refer to as 6S.

Practitioners of 5S will tell you that safety is integrated into, and is an important component, of each S. 6S proponents feel safety is important enough to deserve its own stage of implementation and will have specific safety-related tasks that are part of that stage.

What’s my opinion? I tend to lean more toward 5S. The reason I do this isn’t because I don’t think safety deserves its own stage. Quite the contrary, I believe safety is important enough to deserve its own unique initiative, separate from all other roles and functions within an organization. At Utah Lean Six Sigma Training Center we teach that all of continuous improvement is based on the respect that we have for our colleagues and coworkers. A major part of that respect is an emphasis on safety.

Do What Works for YOU!

All that being said, here is one thing I know for certain: DO WHAT’S RIGHT FOR YOUR ORGANIZATION! If that means a 5S program with an independent safety program, then great! If that means you implement a robust 6S program and roll safety into that initiative, then great! The number of ways to implement continuous improvement are as numerous as the unique organizations dotting the globe. But whatever you do, give safety – and the people you work with – the respect they deserve.

Want to Learn More?

The Yellow Belt class taught at Utah Lean Six Sigma Training Center covers, among other useful topics, the details of 5S. The Green Belt course covers in detail how to implement, support, and maintain a 5S implementation along with the cultural aspects of sustainment. We have classes taught throughout the year, so check out the course calendar and register for your training today!

See you in class!

by Craig Johnson | Aug 28, 2019 | Education

I recently came across this video and, as many of you did, laughed when I saw the boy retrieve the stick. I love how the man looks at the boy in disbelief. My favorite part, however, is how the boy, in innocent oblivion, goes right back to the shoreline ready for another attempt to rescue the flip flop.

After a good laugh I got to thinking, “How often do we see this in business?” We have a business process and we train our team to follow the process: USE A STICK TO RESCUE FLIP FLOPS FROM THE WATER.

Without defining the objective of what we’re doing, our team may innocently believe that the purpose of the process is to use the stick and that rescuing the flip flop is a byproduct of the process. Then when we see our team dutifully using sticks we may have the knee-jerk reaction of “Don’t they have any common sense?” or “It should be obvious!” We often ascribe blame to our team when the fault is actually in us.

As leaders we have a very different view of our processes. It is our job to communicate the WHY of processes, not just the HOW. At Utah Lean Six Sigma Training Center we train you so that you can effectively communicate the how and why of even the most intricate of processes using a variety of tools. One of those tools is standard work.

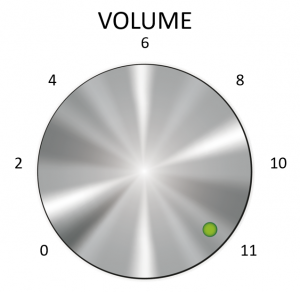

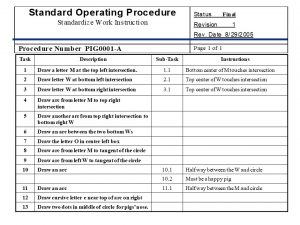

STANDARD WORK

Standard work is a tool that identifies the sequence in which a job should be performed. It may include visual tools such as illustrations of what is good and what is bad. Standard work may also illustrate how each step relates to other steps. This gives process operators critical information on how their roles affect or can be affected by others. You can learn about standard work and many other Lean Six Sigma topics by attending one of our Green Belt courses. In that class we learn how to use standard work using the classic exercise of drawing a pig! It’s one of our favorite learning exercises because it’s fun, engaging, and illustrates the importance of standard work.

At Utah Lean Six Sigma Training Center we love to teach these and many other concepts. Register for one of our upcoming classes today to improve you, your organization, or your team.

by Craig Johnson | Aug 7, 2019 | Adversity

“The only real mistake is the one from which we learn nothing.”

– Henry Ford

FAILURE

It’s such a nasty word. When I read it, I can actually feel my stomach drop. However, I think it’s also one of the most important words in the English language. I recently had a rough encounter with failure. I’m trying my best to come out on the other side a better man. While I can’t say that I’ve made that transition just yet, I’m keeping my eye on the prize. Here are some lessons I learned when something I love turned into something I strongly disliked.

It’s important to be passionate about the things you do. This is true professionally, personally, spiritually, etc. One of the reasons I launched Utah Lean Six Sigma Training Center is because professionally I am passionate about two things: teaching and improving. They go hand-in-hand.

One of the things about which I’m passionate in my personal life is obstacle racing. While this mainly consists of participating in Spartan Races in and around Utah, I’ve done many others. I’m passionate about obstacle racing because my body is very well suited to the obstacles. Simply put, the obstacles are fun for me. I get to swing on monkey bars, climb ropes, throw spears, and generally have a wonderful time acting like a 44-year-old kid. I always enjoy my races.

That is, until last Saturday.

I most certainly did not enjoy my attempt at the Spartan Ultra.

Notice how I wrote “attempt” there? I made it through 18 miles and 39 obstacles of the 31 mile, 74 obstacle race before I missed a time deadline and was cut from the course.

Let me make one thing clear: while there’s always some aspects of each race that I would like to see done differently, my failure is not the fault of Spartan Race. That failure falls squarely on my shoulders. In very general terms, I wasn’t prepared for the aggressive climbs I encountered. 5500’ of elevation gain in those 18 miles wiped me out.

Lesson Learned: “Surround yourself with good people who encourage and love you. There are always ups and downs, no matter how successful you are.” – Liana Liberato

My training for the Spartan Ultra started about 6 months prior to the event. This race, as all of them are, was dedicated to my wife and children. Because I felt as though I had let them down I had to choke back tears as I called my wife to inform her of my failure. I was heartbroken. But even though I was hurting inside, I laughed and laughed all weekend long because of the wonderful friends and family that shared this experience with me. They didn’t let me dwell on my failure. They were exactly what I needed in the immediate aftermath.

Lesson Learned: “When you’re going through hell, keep going!” – Winston Churchill

During the race I was experiencing nasty cramps in my calves. I knew from experience that I would eventually get calf cramps. For me, they typically start around mile six or seven of a race and quickly subside, but these started early around mile five. I tried everything to get them to go away: I stretched my calves, I drank electrolyte infused water. My team mate even gave me a couple mustard packets to gag down! All of those treatments would give me temporary relief and eventually those temporary fixes gave way to more permanent solutions as my body caught up on whatever it was lacking. By mile 15 I realized that the cramps were gone and I was moving fairly comfortably again.

Lesson Learned: “Endings don’t have to be failures, especially when you choose to end a project or shut down a business… Even the best gigs don’t last forever. Nor should they. – Samin Nosrat

Right around mile 15 I knew I wasn’t going to make it to the transition area in time to continue with the race. Even if I had made the time deadline, I simply did not have another lap in my gas tank. Missing the deadline was a mercy killing. Considering my desire to actually live another day, and the realization that I wouldn’t make the cutoff, the rest of my portion of the race became much more enjoyable. The weight of futile effort had been lifted from off my shoulders.

Lesson Learned: “You build on failure. You use it as a stepping stone. Close the door on the past. You don’t try to forget the mistakes, but you don’t dwell on it. You don’t let it have any of your energy, or any of your time, or any of your space.” – Johnny Cash

In the days following the race I’ve had the opportunity to do some honest root cause analysis of my failure. There are a number of causes (you’ll notice I used the plural word “causes”! Read more about why that’s important here.), but chief among them is my lack of training. My good friend and gifted runner JD Bowns told me that in order to prepare, one must get used to spending a lot of time on one’s feet. I didn’t do that. I trained, but not long enough. Looking back, I should have known that my obstacle proficiency was solid, but my running was sub-par. Learning from failure and knowing what you need to do to achieve success is one of the most beautiful things in life. It allows us to turns weaknesses into strengths and emotionally this painful event is now a positive driving force, pushing me on to bigger and better things.

Lesson Learned: “Gratitude is not only the greatest of virtues but the parent of all others.” – Marcus Tullius Cicero

There really are so many lessons to be learned from failure. Certainly more than I’ve listed here. The last bit of knowledge I will share is something I’ve known for many years and has done more to bring me joy than almost any other: gratitude will bring you joy. I’m grateful for my failures. Almost without fail, they make me a better person.

by Craig Johnson | Jul 19, 2019 | Education

Admission time.

I’m a superficial movie fan. In fact, the less I have to think about a plot the better.

I love action-packed sci-fi. I love it when a movie climaxes in the one gigantic battle and the hero single-handedly saves the day. Because that’s exactly what happens in real life, right?!

Yeah, no.

In real life victories are made up of many small wins. One of my mentors called these “base hits”.

In baseball, base hits are often rather routine plays that don’t garner much attention by themselves, especially the first one of the inning. They are, however, positive plays that affect the outcome of the game, but only if there come in succession. With each successive base hit, even if there’s an out in between (just not more than two), the potential outcome of those base hits keeps getting higher and higher. After the first base hit, the next at-bat has the potential for two runs. After the second base hit, the next at-bat has the potential for three runs. Eventually, each successive at-bat has the potential of a grand slam!

In baseball, base hits are often rather routine plays that don’t garner much attention by themselves, especially the first one of the inning. They are, however, positive plays that affect the outcome of the game, but only if there come in succession. With each successive base hit, even if there’s an out in between (just not more than two), the potential outcome of those base hits keeps getting higher and higher. After the first base hit, the next at-bat has the potential for two runs. After the second base hit, the next at-bat has the potential for three runs. Eventually, each successive at-bat has the potential of a grand slam!

Out continuous improvement activities are much the same. Our small victories are what make us successful and will carry our organizations through. Each successive small victory builds on the potential of the ones that preceded it. Eventually the cumulative benefits of our wins set us up for major breakthroughs.

As continuous improvement leaders we can’t let ourselves be seduced into ignoring small projects for the lure of potentially huge, but much less likely for success projects. As always, it’s a delicate balance. We need to stand ready to support our team by watching out for grand slam opportunities, but also make sure we’re coaching them to take advantage of every success.

Because that’s how we win the game.

Mistake proofing, also known as error proofing, is a concept that has existed longer than anyone can accurately define. Poka Yoke, the Japanese term for mistake proofing, was formally defined and systematized by Shigeo Shingo of Toyota in the 1960’s. It has become a standard for creating processes that are designed to either not be able to produce a specific defect or automatically detect and reject a specific defect. Mistake proofing has been used across industries to create efficient workspaces and to create safe environments. To be able to implement mistake proofing we need to understand the types of mistakes people can make and then be able to put countermeasures in place to prevent those mistakes.

Mistake proofing, also known as error proofing, is a concept that has existed longer than anyone can accurately define. Poka Yoke, the Japanese term for mistake proofing, was formally defined and systematized by Shigeo Shingo of Toyota in the 1960’s. It has become a standard for creating processes that are designed to either not be able to produce a specific defect or automatically detect and reject a specific defect. Mistake proofing has been used across industries to create efficient workspaces and to create safe environments. To be able to implement mistake proofing we need to understand the types of mistakes people can make and then be able to put countermeasures in place to prevent those mistakes.

When I originally wrote that headline, I thought of that wonderful scene on This is Spinal Tap where the musician was talking about how his speakers were louder than anyone else’s. When everyone else’s had a volume knob that went from 0 to 10, his went up to 11. The only thing that was different about his speaker was the volume knob. It wasn’t actually louder, but in his mind, 11 was obviously louder than 10. That’s how I jokingly first thought about the 5S vs. 6S debate.

When I originally wrote that headline, I thought of that wonderful scene on This is Spinal Tap where the musician was talking about how his speakers were louder than anyone else’s. When everyone else’s had a volume knob that went from 0 to 10, his went up to 11. The only thing that was different about his speaker was the volume knob. It wasn’t actually louder, but in his mind, 11 was obviously louder than 10. That’s how I jokingly first thought about the 5S vs. 6S debate. Sort: identify only the inventory, tools (including information tools) and maintenance items absolutely required to support the daily activities of the work area.

Sort: identify only the inventory, tools (including information tools) and maintenance items absolutely required to support the daily activities of the work area.

In baseball, base hits are often rather routine plays that don’t garner much attention by themselves, especially the first one of the inning. They are, however, positive plays that affect the outcome of the game, but only if there come in succession. With each successive base hit, even if there’s an out in between (just not more than two), the potential outcome of those base hits keeps getting higher and higher. After the first base hit, the next at-bat has the potential for two runs. After the second base hit, the next at-bat has the potential for three runs. Eventually, each successive at-bat has the potential of a grand slam!

In baseball, base hits are often rather routine plays that don’t garner much attention by themselves, especially the first one of the inning. They are, however, positive plays that affect the outcome of the game, but only if there come in succession. With each successive base hit, even if there’s an out in between (just not more than two), the potential outcome of those base hits keeps getting higher and higher. After the first base hit, the next at-bat has the potential for two runs. After the second base hit, the next at-bat has the potential for three runs. Eventually, each successive at-bat has the potential of a grand slam!